Since 2009 Aamgard Engineering develops and builds motorsport wiring looms and cablings for race cars, special vehicles, sport boats and test beds. Today, continuous enhancing of personal skills and technical working methods enables us to meet customer requirements from clubsport to Formula 1.

Before building of bespoken electrics it always needs professional system planing and overmeasure. Both is done as well at the customer's location, as inside our workshop. Further project steps are:

- preparation of drawings, schematics, loom plans etc.

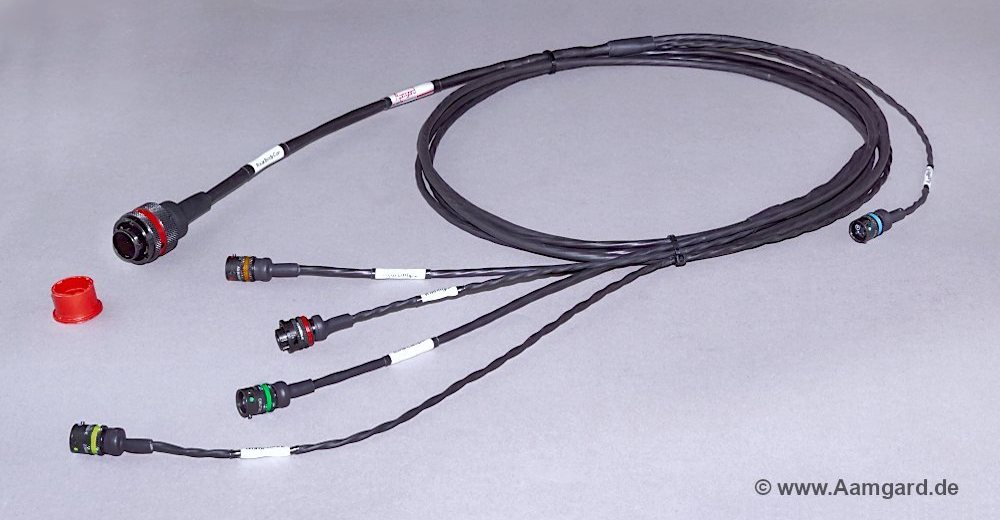

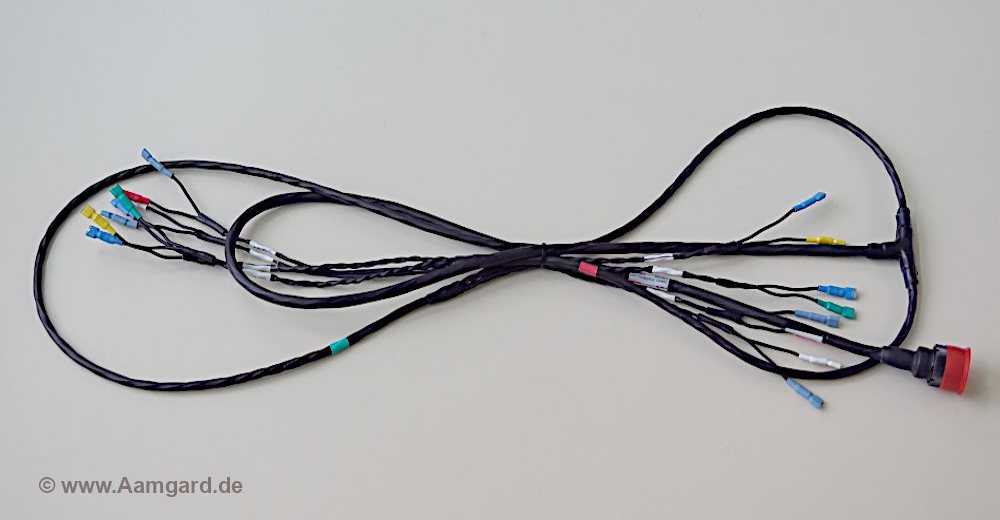

- building and pre-testing of electric harnesses and components

- system test and basic configuration of displays and control units

- installation of all components inside the car or at the test bed

- start-up, final test and concluding project documentation

Whether racecar, oldtimer, youngtimer, sport boat or construction machinery: Most important for reliable function and durability of an electric system is not to use absolute high-end and most expensive materials. Key is to choose suitable materials and components and to process them with high quality craftmanship. For this quality craftmanship Aamgard Engineering stands since more than fifteen years.